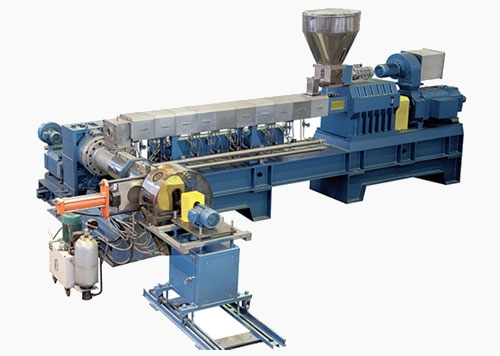

Dual Stage Extrusion Line

- Application: All

- Market Type:After Market

- Price: Inquiry For It?

Quick Details

-

Material:

Plastic

-

Shape:

T-Profile

- OE Experience:

No

Product Name:Dual Stage Extrusion Line

Dual Stage Extrusion Line

Application

All

Product Description:

| Dual Stage Extrusion Line |

|

|

By either single screw extruder or twin screw extruder the process goes in this sequence: solid conveying, melting, compounding, degassing and extruding. Normally, each step requires different screw structure, different operating conditions, such as RPM, barrel heating temperature, material pressure, etc. But as a matter of fact, all these steps perform through the same screw shaft. That is, the rotary speed of screw is same and the temperatures will influence on each step. All these affect the pressure build-up and energy input which are so far not possible to be realized for every inpidual step. For instance, in order to increase the output of single screw extruder, in conveying part, we would use the screw structure like this: deeper groove depth, longer screw distance, higher RPM, lower die pressure and lower extruding temperature. But higher RPM means faster conveying speed and this would make a negative effect on melting. Sometimes for better mixing, we would use kneading elements which can provide better compounding as well as higher temperature. If the material being processed is heat-sensitive, this kneading element may get it degraded. The same problem would happen on a twin screw extruder. To avoid these problems we develop the idea of dual stage extrusion line.The first extruder is of GTS twin screw mainly for melting and compounding, and the second extruder is of SJ single screw mainly for pressure build-up and extruding. Application Heat-sensative or Shear-sensative Materials like PVC, XLPE Specifications

|

Supplier Details

You May Like:

-

GTS-H High Torque Twin Screw Extruder

Application: All

-

Parallel Co-Rotating Twin Screw Extruder

Application: All

-

PE-RT, PE-X Pipe Extrusion Line

Application: All

-

Rubber Extrusion Xc0568

Application: Auto

OEM No: Xc0568

-

STAINLESS aluminium extrusions industrial stamping ...

Application: Universal

Related Product Tags:

aluminum auto component , aluminum auto components , aluminum extruded components , aluminum extrusion , inner sleeve , Alloy ExtrusionPlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.